Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

How Much is the General Concave Lens Manufacturing Price?

Concave lenses are widely used in many applications, ranging from scientific research to consumer goods. As a concave lens manufacturer, we understand that you may have many questions about concave lens manufacturing prices. In this blog post, we will answer some of the most frequently asked questions about concave lens manufacturing prices and provide you with some useful insights.

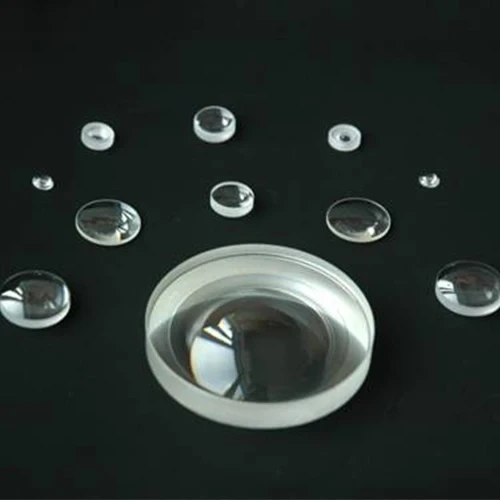

What are concave lenses?

Concave lenses, also known as diverging lenses, are lenses that are thicker at the edges than at the center. They are used to spread out light waves and form a virtual image that is smaller than the object. Concave lenses are widely used in telescopes, cameras, and eyeglasses.

How are concave lenses manufactured?

There are several methods to manufacture concave lenses, including

1. Molding

2. Diamond turning

3. CNC machining

4. Glass blowing

The method used to manufacture the concave lens will depend on the size, shape, and material used.

How much does it cost to manufacture concave lenses?

The price of manufacturing concave lenses depends on several factors, including the following:

1. Material

2. Size and shape

3. Quantity

4. Manufacturing method

5. Coating

6. Tolerances

7. Lead time

Material: The material used to manufacture the concave lens will have a significant impact on the cost. Materials can range from common glasses, including BK7, Flint glasses, and others, to more exotic materials like Zinc Selenide, Germanium, or Silicon.

Size and shape: The size and shape of the concave lens will also influence the cost. Larger lenses require more material and involve more processes, while more complex shapes may take longer to manufacture.

Quantity: The quantity of concave lenses ordered will also affect the price per unit. Bulk orders usually have a lesser unit price as compared to smaller ones.

Manufacturing method: The manufacturing method used will also influence the cost. Some methods are more expensive than others, but some yield better efficiency and reproducibility.

Coating: Some applications require a specific type of coating, such as anti-reflective coating, for the lens to be effective. This added step will have an additional cost, but it may also add value to the lens.

Tolerances: Accuracy is crucial for concave lenses, some applications require rigorous standards, such as aerospace and other scientific fields, where the cost may be higher and the tolerance range is very tight.

Lead time: The lead time or the time required to manufacture the lenses can play a significant role in the cost. Quicker turnaround means higher costs and longer lead times, lower your costs as well.

Conclusion

The manufacturing price of concave lenses varies and depends on several factors, including material, size, quantity, manufacturing methods, coatings, tolerances, and lead time. As a concave lens manufacturer, we strive to provide affordable and high-quality concave lenses to meet your needs. If you are interested in buying concave lenses, please get in touch with us for the concave lens manufacturing pricelist.