Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Innovations and Applications: A Deep Dive into the Light Bar Prism Factory Landscape

The world of lighting technology is ever-evolving, and at the heart of this innovation lies the light bar prism factory, a hub of creativity and engineering that shapes the way we experience light. Light bar prisms are integral components in various lighting applications, known for their ability to manipulate and direct light with precision. In this comprehensive blog post, we will explore the intricate processes of light bar prism manufacturing, the latest advancements from light bar prism manufacturers, and the wide array of applications that benefit from this technology. Join us as we illuminate the inner workings of the light bar prism factory and its significant impact on the lighting industry.

I. Introduction to Light Bar Prism Technology

A. What is a Light Bar Prism?

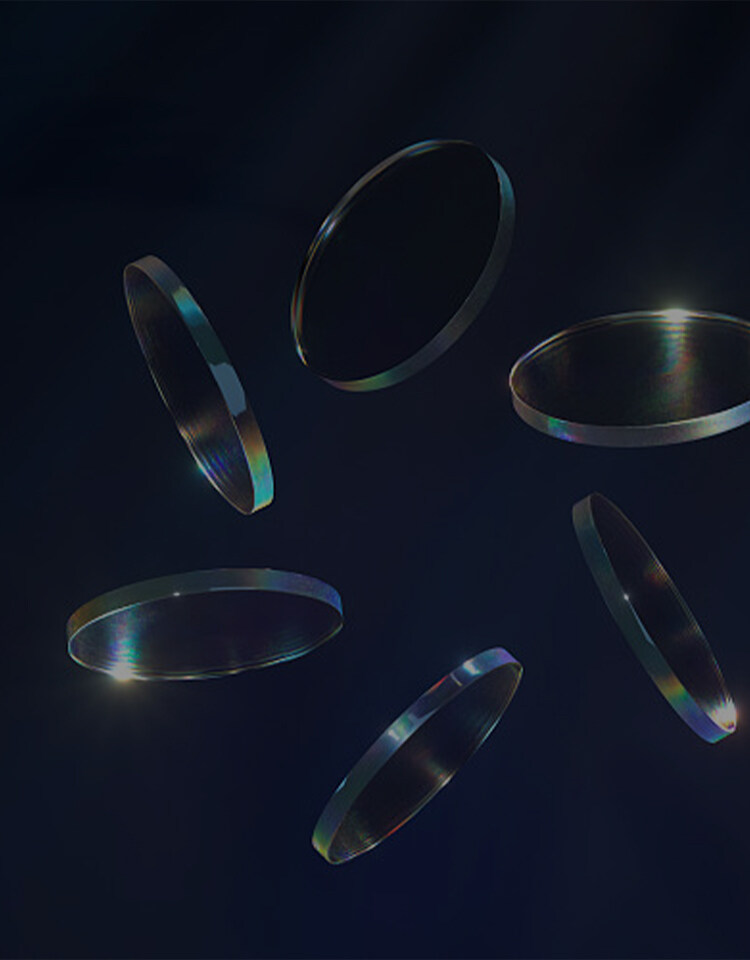

A light bar prism is a specialized optical component designed to manipulate light in precise ways. It is typically a slender, transparent piece made from materials like glass or acrylic, which has been shaped and polished to refract light. The unique properties of a light bar prism allow it to bend, split, or spread light beams, making it an essential element in various lighting applications where directional control and uniform light distribution are required.

B. The Science Behind Light Bar Prisms

The science of light bar prisms is rooted in the principles of optics, particularly refraction. When light passes through a prism, it changes direction due to the difference in the refractive index between the air and the material of the prism. This can cause light to spread out into its constituent colors, as seen in a rainbow, or be directed in a specific pattern. The angle and surface finish of the prism determine the exact behavior of the light, allowing engineers to design prisms that achieve the desired lighting effect.

C. Importance in Modern Lighting Solutions

Light bar prisms are crucial in modern lighting solutions because they offer a high degree of control over light without significant loss of intensity. This makes them ideal for applications that require bright, focused, or evenly distributed light. They are commonly used in LED lighting systems, where they help to diffuse light and reduce glare, enhancing the visual comfort and effectiveness of the lighting installation.

II. The Light Bar Prism Factory: An Overview

A. The Manufacturing Process

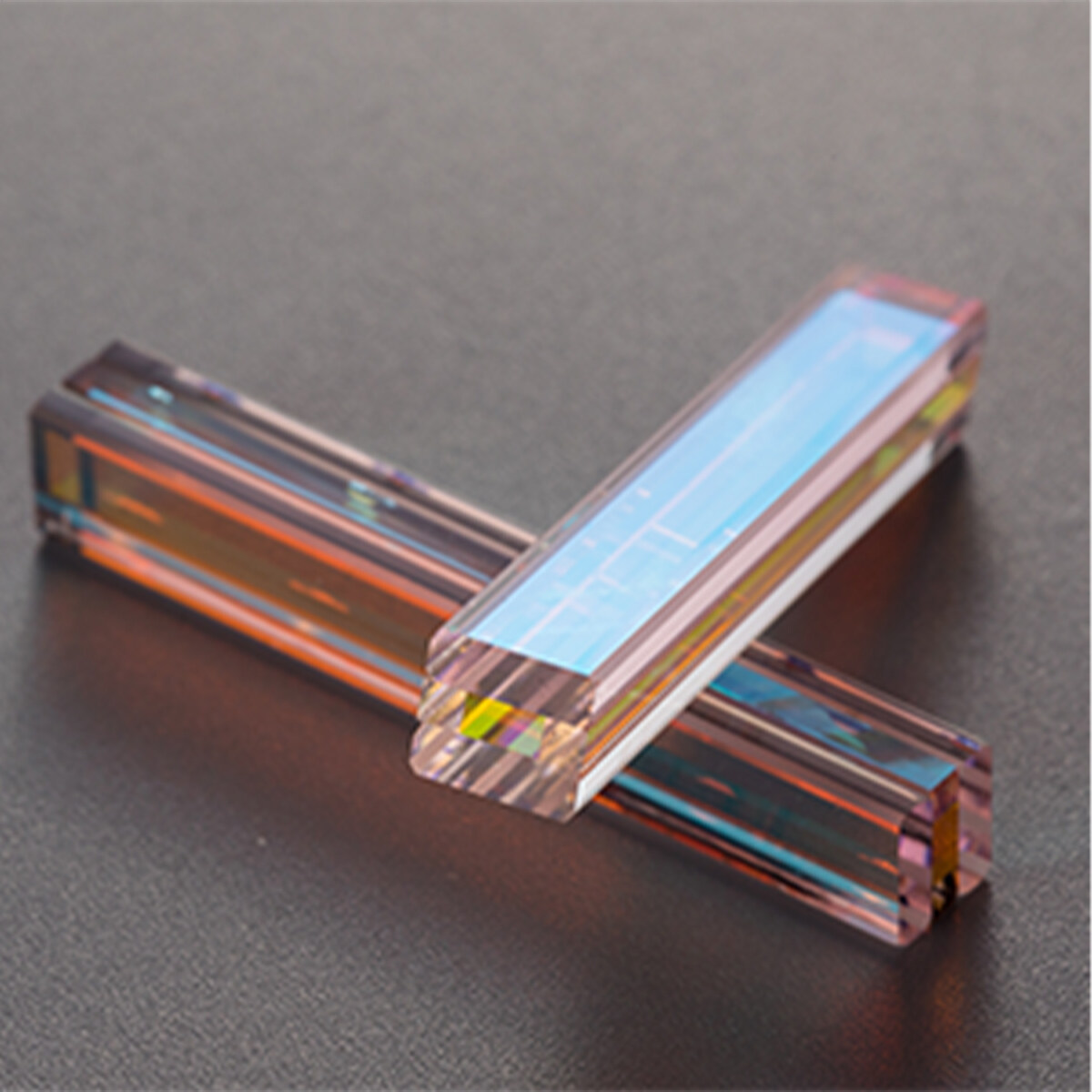

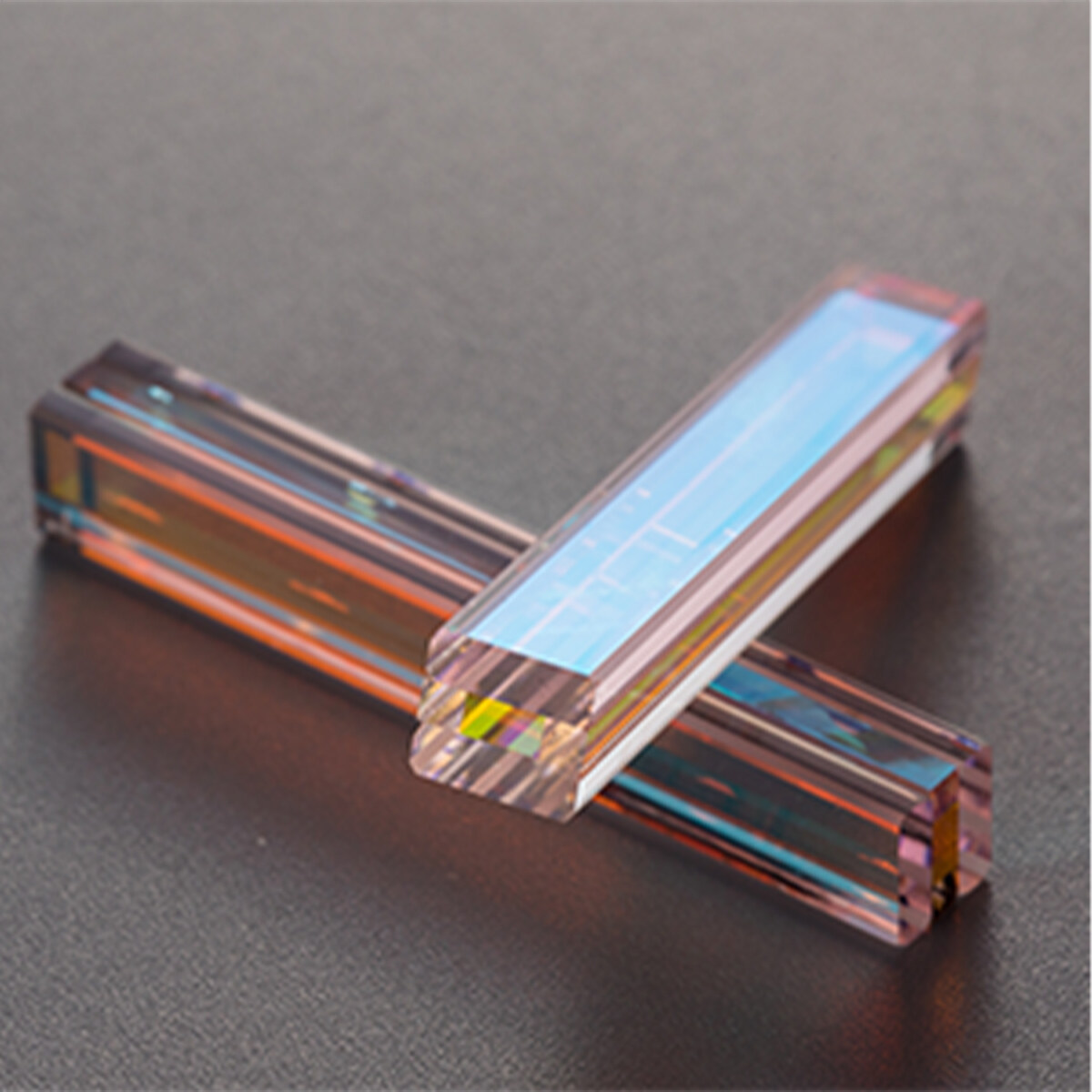

The manufacturing process at a light bar prism factory involves several key steps. It begins with the selection of raw materials, which must be of high optical quality and free from imperfections. The material is then cut into the desired shape, followed by a precision polishing process to create smooth surfaces that will interact with light as intended. Advanced machinery and meticulous quality control are essential to ensure that each prism meets the exact specifications required for its intended use.

B. Materials and Design Considerations

When it comes to materials, light bar prism manufacturers often choose between glass and various types of plastic, each with its own advantages. Glass prisms offer excellent clarity and durability, while plastic prisms are lighter and more impact-resistant. The design of the prism must also take into account factors such as the light source’s characteristics, the desired distribution of light, and the end application’s environmental conditions.

C. Ensuring Quality in Production

Quality assurance is paramount in the production of light bar prisms. This includes regular inspection of raw materials, monitoring of the manufacturing process, and rigorous testing of the finished prisms. Light bar prism factories often employ advanced optical measurement equipment to verify that each prism meets the required performance standards. This attention to quality helps to maintain the factory’s reputation and ensures customer satisfaction.

III. Advancements in Light Bar Prism Manufacturing

A. Innovations from Light Bar Prism Manufacturers

Light bar prism manufacturers are constantly pushing the boundaries of optical engineering to enhance the performance and versatility of their products. Recent innovations include the development of micro-structured prisms that can manipulate light with even greater precision, and the use of advanced coating technologies that improve the efficiency and longevity of prisms in harsh environments. Manufacturers are also exploring the integration of nanotechnology to create prisms with unique properties, such as self-cleaning or anti-reflective surfaces.

B. Customization and Tailored Solutions

The ability to provide customized solutions is a key differentiator for light bar prism factories. By working closely with clients, manufacturers can design prisms that meet specific requirements, such as unique light dispersion patterns or integration into complex lighting systems. This level of customization allows for the creation of specialized lighting solutions for niche applications, ensuring that the end product perfectly aligns with the customer’s vision and technical needs.

C. Sustainability in Manufacturing

Sustainability is becoming an increasingly important consideration in the manufacturing of light bar prisms. Factories are adopting eco-friendly practices, such as using recyclable materials, reducing waste, and minimizing energy consumption during production. Some manufacturers are also implementing closed-loop systems to reclaim and repurpose materials, further reducing the environmental impact of their operations.

IV. Applications of Light Bar Prisms

A. Automotive Industry

In the automotive industry, light bar prisms are used to enhance the performance of vehicle lighting, including headlights, taillights, and interior illumination. Prisms are designed to distribute light evenly, improve visibility, and contribute to the aesthetic appeal of the vehicle. They are also integral to advanced safety features, such as adaptive lighting systems that adjust to driving conditions.

B. Consumer Electronics

Light bar prisms play a crucial role in consumer electronics by improving the quality of display lighting in devices such as smartphones, tablets, and laptops. They help achieve uniform backlighting, reduce glare, and enhance the overall user experience. The compact and efficient design of these prisms makes them ideal for the slim profiles of modern devices.

C. Architectural and Ambient Lighting

Architectural and ambient lighting applications benefit greatly from the use of light bar prisms. They are used in commercial and residential spaces to create specific moods, highlight architectural features, and provide functional lighting that is both efficient and aesthetically pleasing. Prisms can be tailored to suit the design of a space, offering architects and designers a versatile tool for their lighting projects.

V. Choosing the Right Light Bar Prism Factory

A. Criteria for Selection

Selecting the right light bar prism factory involves several criteria, including the quality of the prisms produced, the factory’s ability to meet deadlines, and the level of customer service provided. Potential clients should also consider the factory’s track record for innovation, its use of sustainable manufacturing practices, and its ability to offer competitive pricing.

B. The Role of Expertise and Experience

Expertise and experience are critical factors when choosing a light bar prism factory. A manufacturer with a long history in the industry is likely to have a deep understanding of optical principles and a proven ability to deliver high-quality products. Experienced factories are also better equipped to handle complex projects and offer insightful recommendations based on past projects.

C. Evaluating the Portfolio of a Light Bar Prism Manufacturer

A manufacturer’s portfolio can provide valuable insights into their capabilities and the range of projects they have successfully completed. When evaluating a factory’s portfolio, look for diversity in applications, innovation in design, and testimonials from satisfied clients. A strong portfolio is often indicative of a manufacturer’s ability to deliver quality prisms that meet or exceed expectations.

VI. The Future of Light Bar Prism Technology

A. Emerging Trends in Lighting

The lighting industry is witnessing a surge in innovation, with trends like human-centric lighting, energy efficiency, and IoT integration leading the way. Light bar prism technology is at the forefront of these trends, offering precise light control and distribution. As the demand for dynamic and customizable lighting solutions grows, light bar prisms are increasingly incorporated into various applications, from automotive to architectural lighting.

B. The Role of Light Bar Prisms in Smart Lighting

Smart lighting systems are becoming more prevalent, and light bar prisms play a crucial role in their functionality. These prisms can be engineered to work with sensors and controllers to adjust lighting conditions in real-time, contributing to energy savings and improved user experiences. The integration of light bar prisms in smart lighting also enables the creation of mood lighting and circadian rhythm-based lighting schemes, which can enhance well-being and productivity.

C. Predictions for Future Developments

The future of light bar prism technology is likely to see advancements in materials and design, leading to even more efficient light diffusion and manipulation. Innovations in nanotechnology and photonics may result in prisms that can dynamically change their optical properties. Additionally, the integration of light bar prisms with emerging technologies like OLEDs and quantum dots is expected to open up new possibilities for ultra-thin and flexible lighting solutions.

VII. Case Studies: Success Stories from Light Bar Prism Factories

A. Automotive Lighting Innovations

Light bar prism factories have played a pivotal role in automotive lighting advancements. For instance, the development of adaptive LED headlights, which use prisms to control light distribution, has significantly improved road safety. These headlights can adjust the beam pattern to avoid blinding oncoming traffic while providing optimal illumination for the driver.

B. Breakthroughs in Consumer Device Displays

In consumer electronics, light bar prisms have enabled the creation of brighter and more energy-efficient displays. A notable success story is the use of prisms in edge-lit LED TVs, which have allowed for slimmer designs without compromising on picture quality. These prisms efficiently direct light across the screen, ensuring uniform brightness and color accuracy.

C. Transformative Architectural Lighting Projects

Architectural lighting has been transformed by the use of light bar prisms, with projects like the illumination of landmarks and public spaces showcasing their potential. Prisms have enabled designers to achieve complex lighting effects and patterns, enhancing the aesthetic appeal and functionality of buildings and urban environments.

VIII. Working with a Light Bar Prism Manufacturer

A. Collaboration for Custom Projects

Collaborating with a light bar prism manufacturer is essential for custom projects that require specialized lighting solutions. Manufacturers can provide expertise in optical design and material selection to meet specific project needs. This collaboration often involves prototyping and testing to ensure the final product meets the desired specifications.

B. Navigating Logistics and Supply Chain Management

Working with a manufacturer also involves managing logistics and supply chain complexities. It’s crucial to establish clear communication channels and timelines to ensure that the production and delivery of light bar prisms align with project schedules. Manufacturers can assist with inventory management, shipping, and handling to minimize disruptions.

C. After-Sales Support and Services

After-sales support is an important aspect of working with a light bar prism manufacturer. This includes warranty services, technical support, and potential product upgrades. A reliable manufacturer will provide ongoing assistance to address any issues that may arise after installation and ensure customer satisfaction.

IX. Legal and Regulatory Considerations

A. Compliance with International Standards

Light bar prism manufacturers must comply with international standards, such as those set by the International Electrotechnical Commission (IEC) and the Illuminating Engineering Society (IES). These standards ensure product safety, performance, and compatibility, which are critical for global market acceptance.

B. Intellectual Property in Light Bar Prism Design

Protecting intellectual property is vital in the competitive lighting industry. Manufacturers and designers must secure patents for their light bar prism designs to safeguard their innovations and maintain a competitive edge. This also involves respecting the IP rights of others to avoid legal disputes.

C. Navigating Global Trade in the Lighting Industry

The global nature of the lighting industry requires manufacturers to navigate trade regulations, tariffs, and customs procedures. Understanding these legal frameworks is essential for smooth international operations and to avoid potential legal issues that could impact business.

X. Conclusion

In conclusion, the light bar prism factory landscape is a testament to the intersection of art and science in the realm of lighting technology. As we have explored, these factories are not just manufacturing hubs but centers of innovation, where the precision of optics meets the demands of modern lighting applications. From the automotive sector to consumer electronics and architectural marvels, light bar prisms are shaping the way we see and interact with light.

As manufacturers continue to push the boundaries with advanced materials, sustainable practices, and smart technology integration, the future of light bar prisms looks bright. With a commitment to quality, customization, and compliance with international standards, the industry is poised to illuminate our world in ways we have yet to imagine, making the collaboration between designers, manufacturers, and end-users more vital than ever. As we move forward, the stories of success and the ongoing evolution of light bar prism technology will undoubtedly continue to fascinate and inspire.