Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

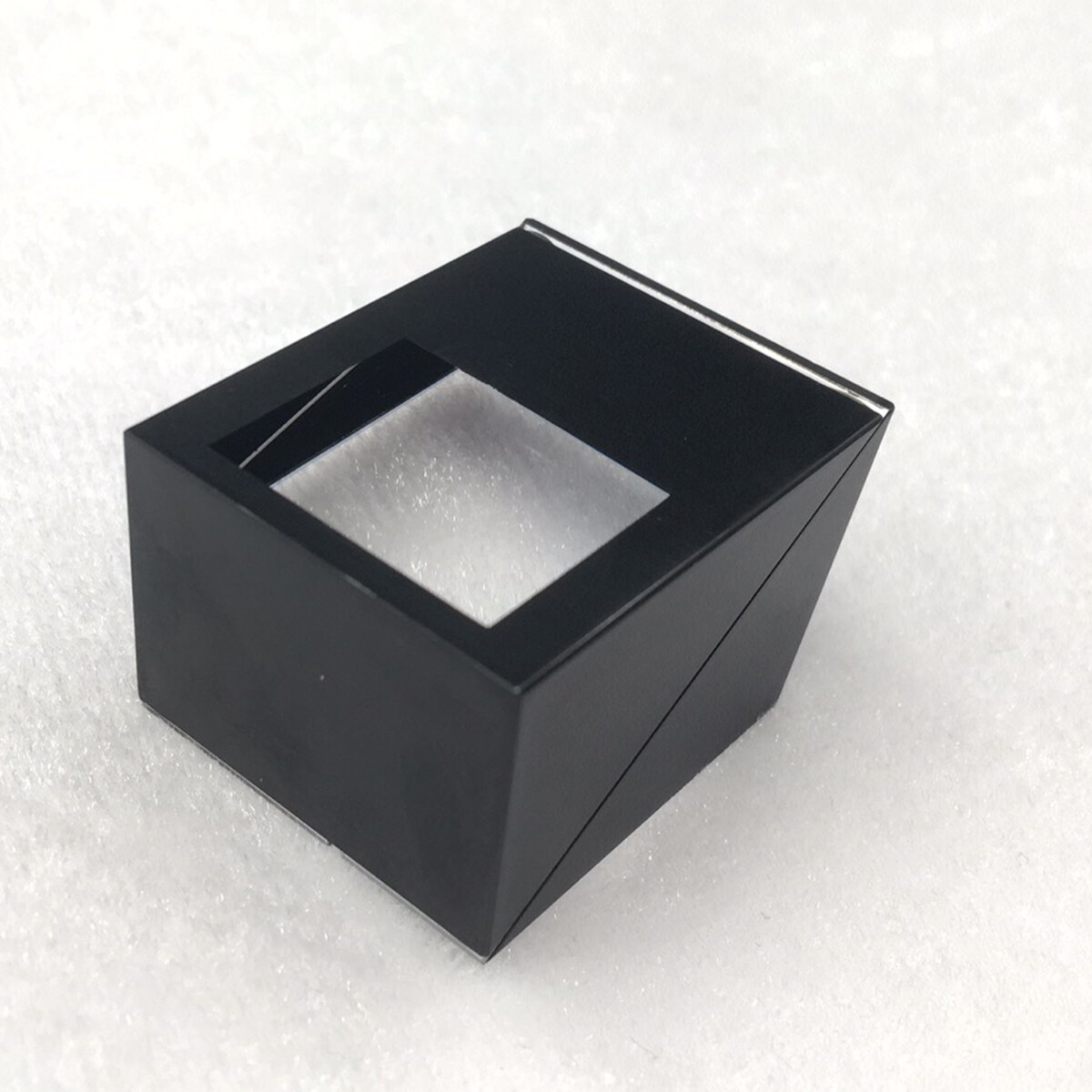

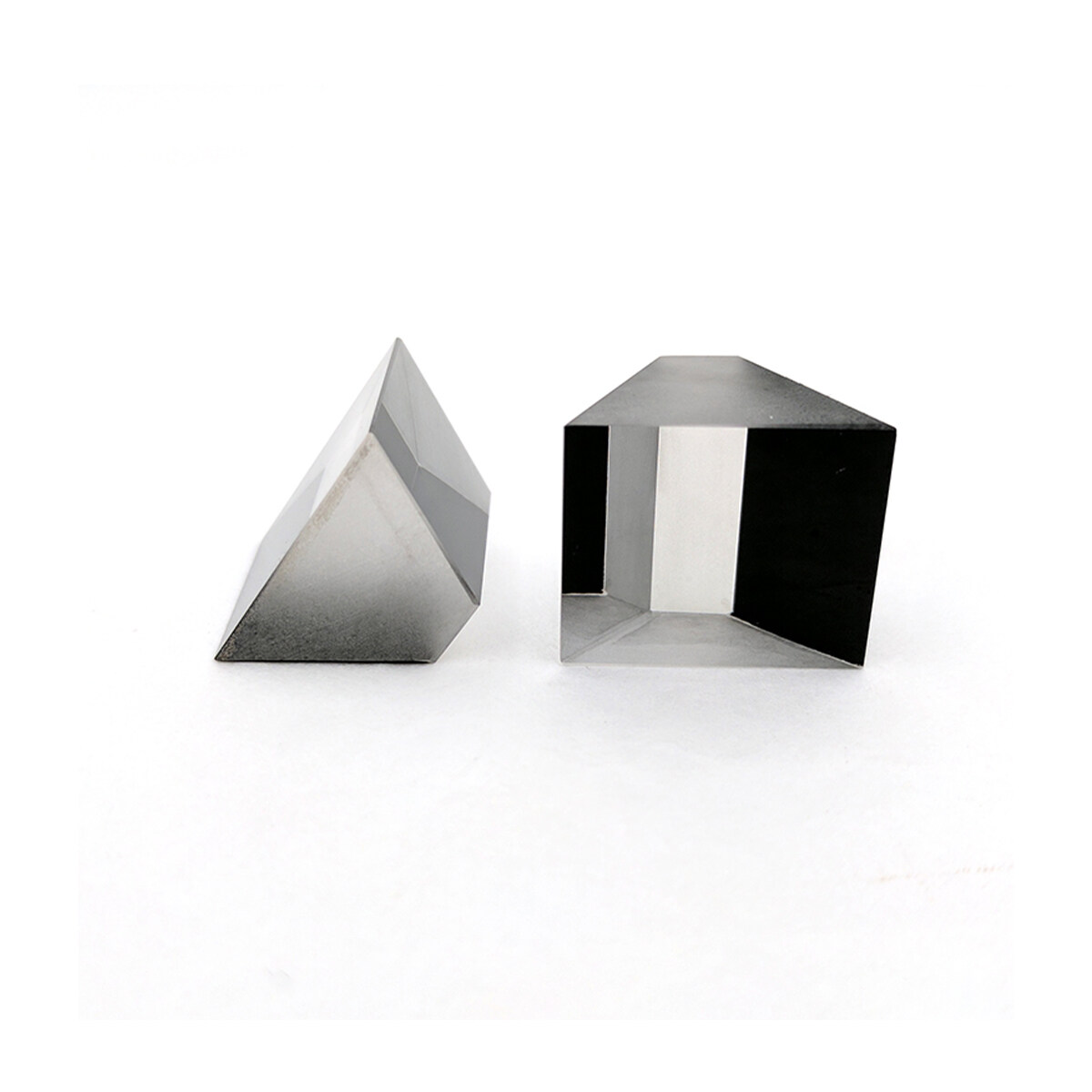

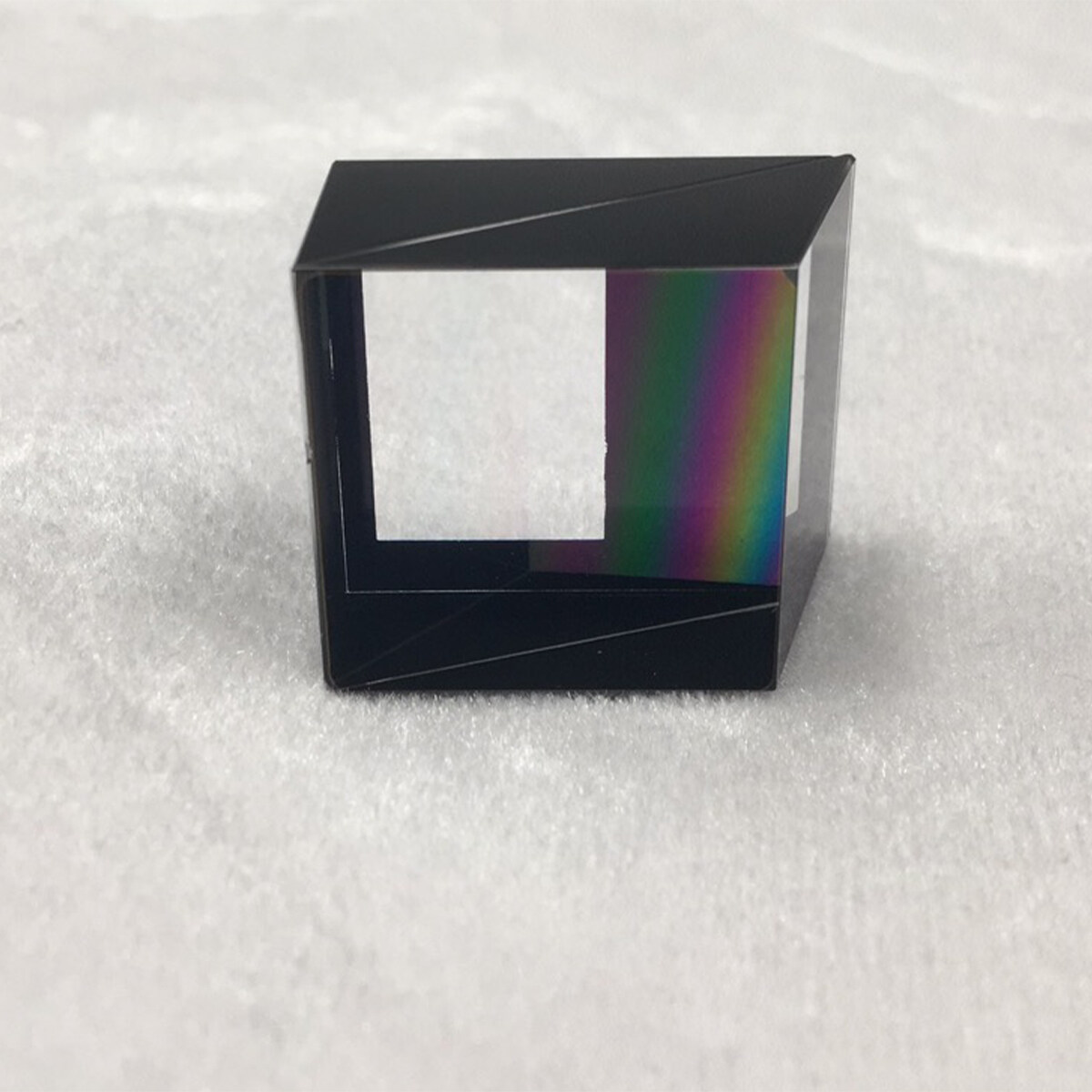

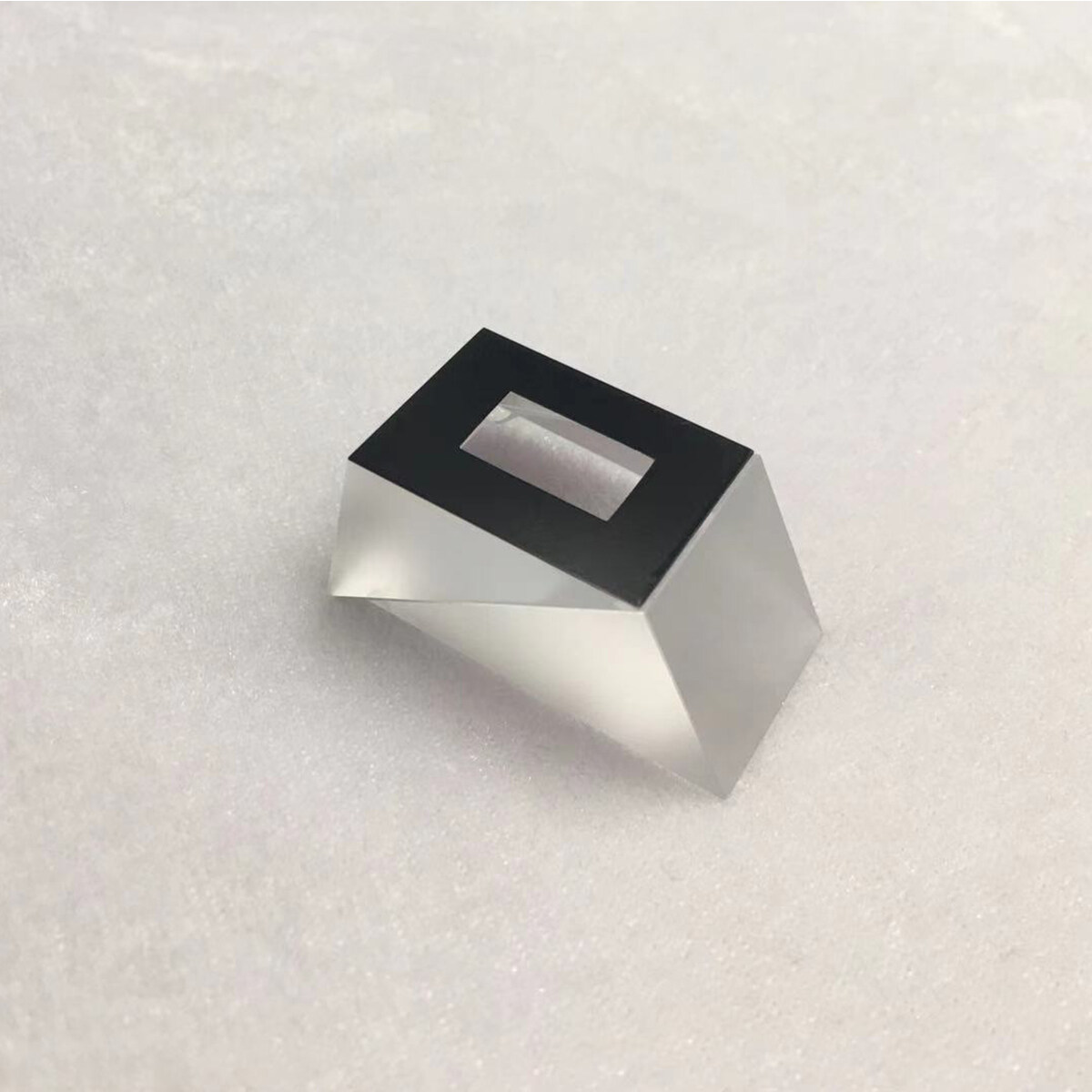

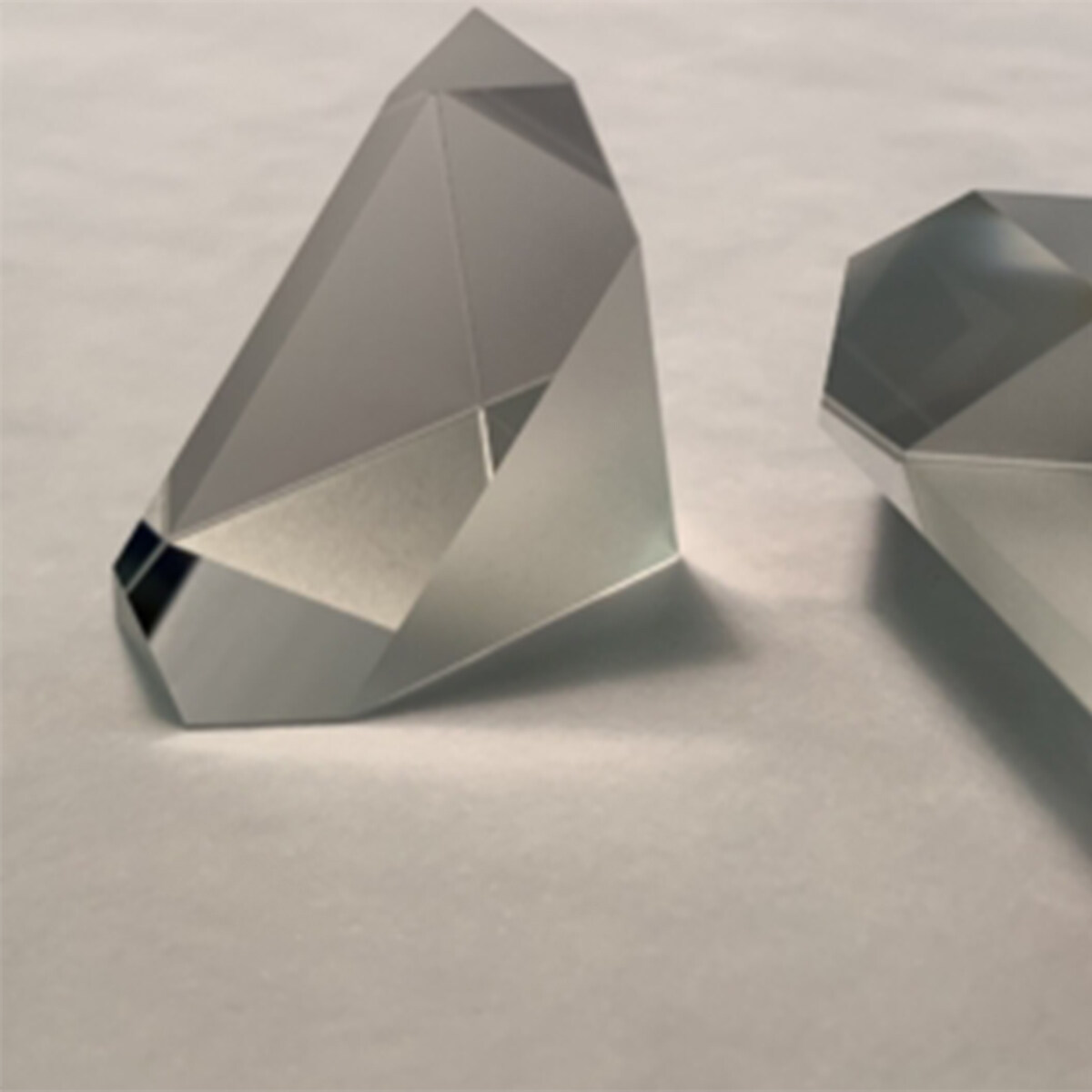

Identification Prism

We are one of the optical glass prism suppliers in china Our Identification Prism is a great tool and highly useful for identifying different colors.

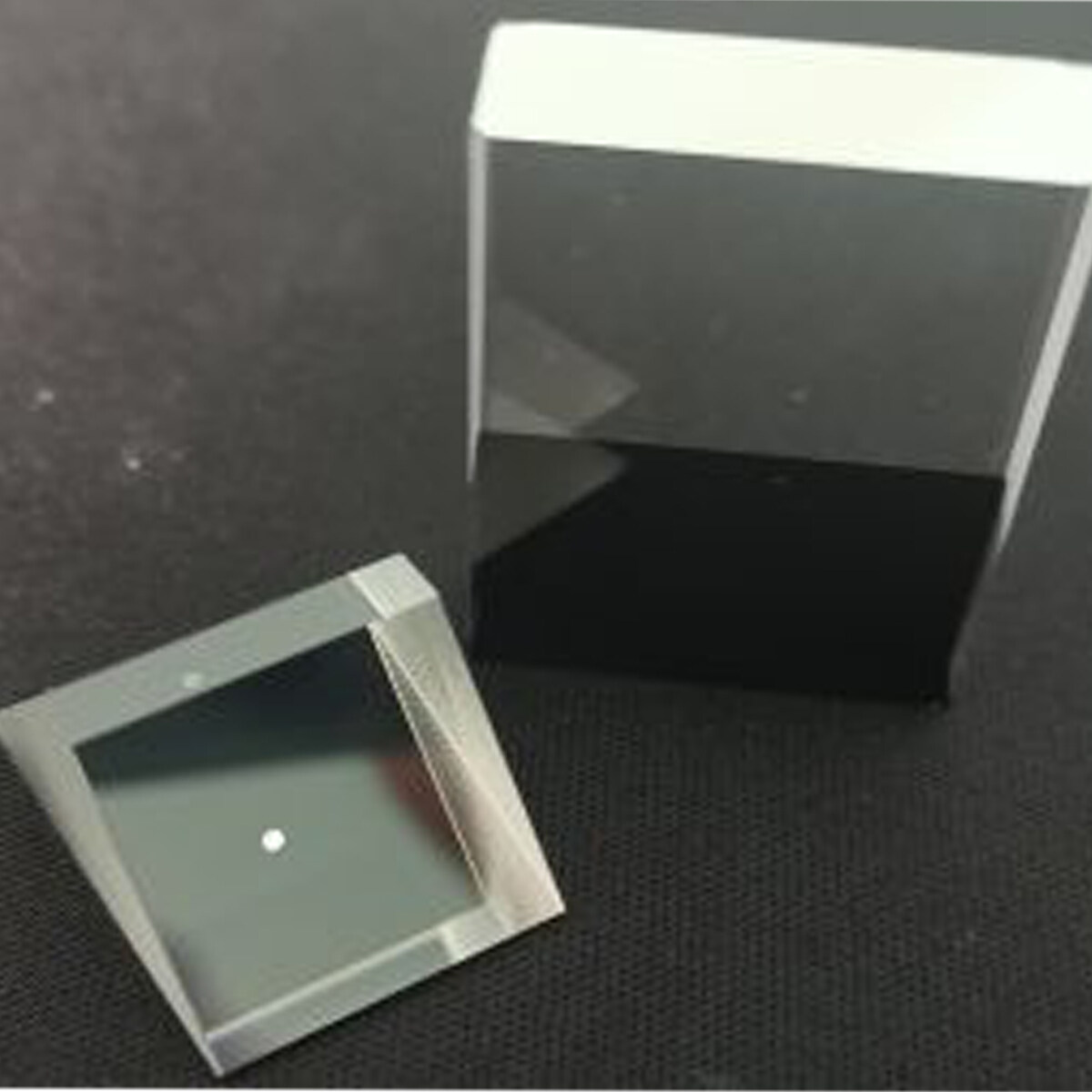

Manufacture of prism

Before delving into the theory of prism, think about its manufacturing process. To be used successfully in most applications, prisms must be manufactured with very strict tolerances and accuracy. Due to the variation of shape, size, and the number of the most important reflector, a large-scale automation process is completely infeasible for prism manufacturing. In addition, most high-precision prisms tend to be manufactured in small quantities, which means that automated processes are unnecessary.

First, obtain a piece of glass (called "glass blank") that meets a specific grade and glass type. Then grind the glass, or use a metal diamond wheel to produce a near-finished product. Most of the glass will be removed from this stage to form a flat but still rough surface.

At this time, the size of the prism that is about to become is very close to the required specification. Next, it is a fine grinding process to remove the cracks under the surface of the surface; This stage is called fine grinding. The scratches left in the first stage will be removed in the second stage. After fine grinding, the glass surface should appear turbid and opaque. In the first two stages, the surface of the prism must be wet to speed up the removal of the glass and prevent the glass itself from overheating.

The third stage includes polishing the prism to the specified accuracy according to the specification requirements. In this stage, the glass will rub against a polyurethane polisher wet with a "grinding slurry", an optical polishing compound that usually contains water mixed with pumice or cerium oxide.

The exact time of the polishing stage depends very much on the required mirror specification. Once polishing is completed, chamfer can be started. In this fourth stage, the edge of the prism will pass through a rotating diamond plate to slightly blunt the sharp edge formed in the above steps.

After chamfering, the finished prism will be cleaned, inspected (manually and automatically), and antireflection (AR) and/or metal reflection coating will be carried out if necessary to further help improve the overall transmittance and/or reflectivity.

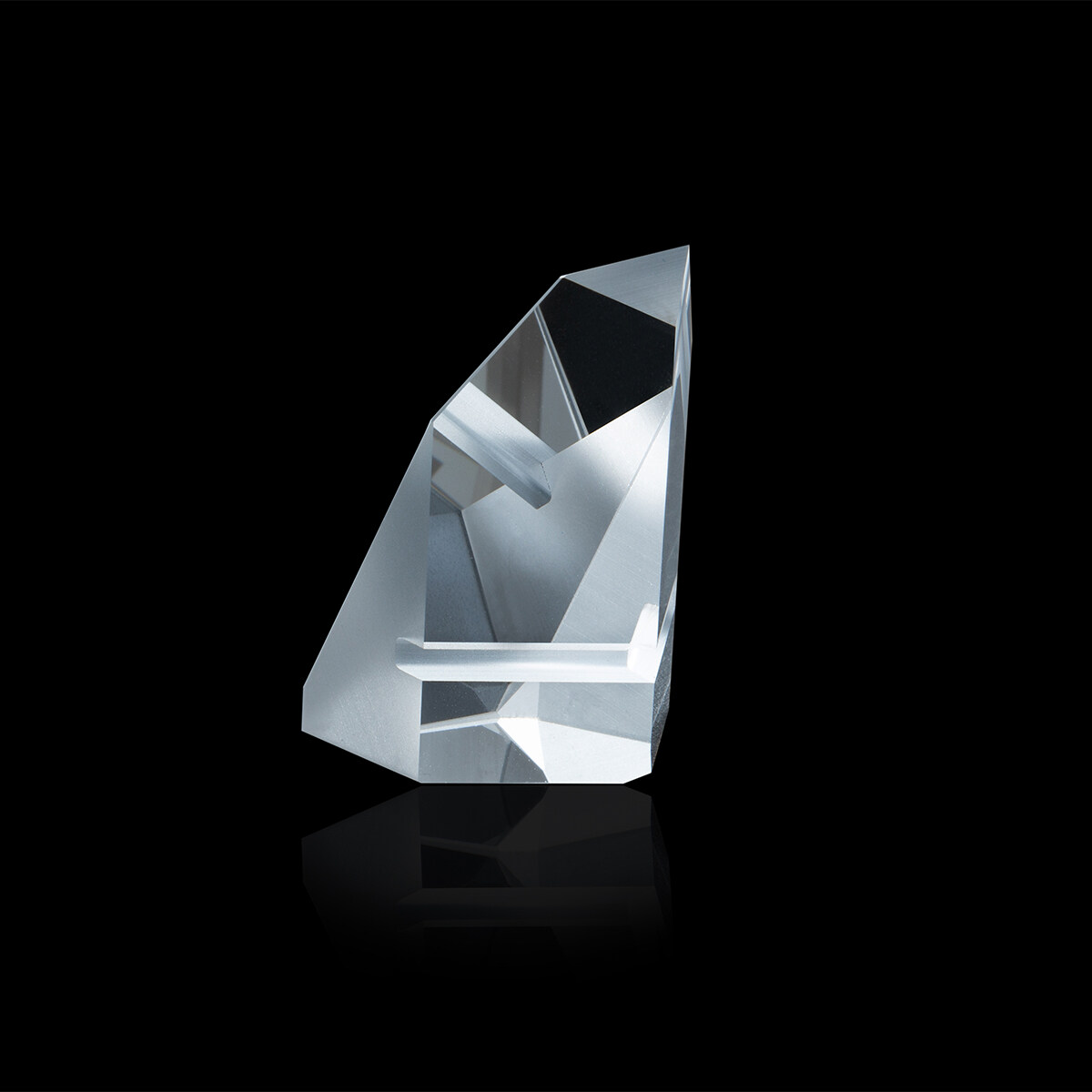

In the whole process of manufacturing prisms, it is necessary to constantly adjust and fix each mirror in progress. Fixing the prism in place involves one of two methods: prevention and contact. Prevent the need to arrange the prism in the metal tool injected with hot wax.

On the other hand, contact is an optical bonding process at room temperature, through which two clean glass surfaces are fastened together through its van der Waals interaction. The contact method is used when high-precision tolerances are required because it does not require other adjustments during the generation, smoothing, or polishing stages to take into account the wax thickness between the prism surface and the contact block.

At every stage of the prism manufacturing process, from production to prevention and contact, a skilled optometrist is required to manually check and adjust the prism surface being processed. Therefore, it requires a lot of labor and requires experience, and skills to complete. The whole process usually requires a considerable amount of time, work, and attention.