Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

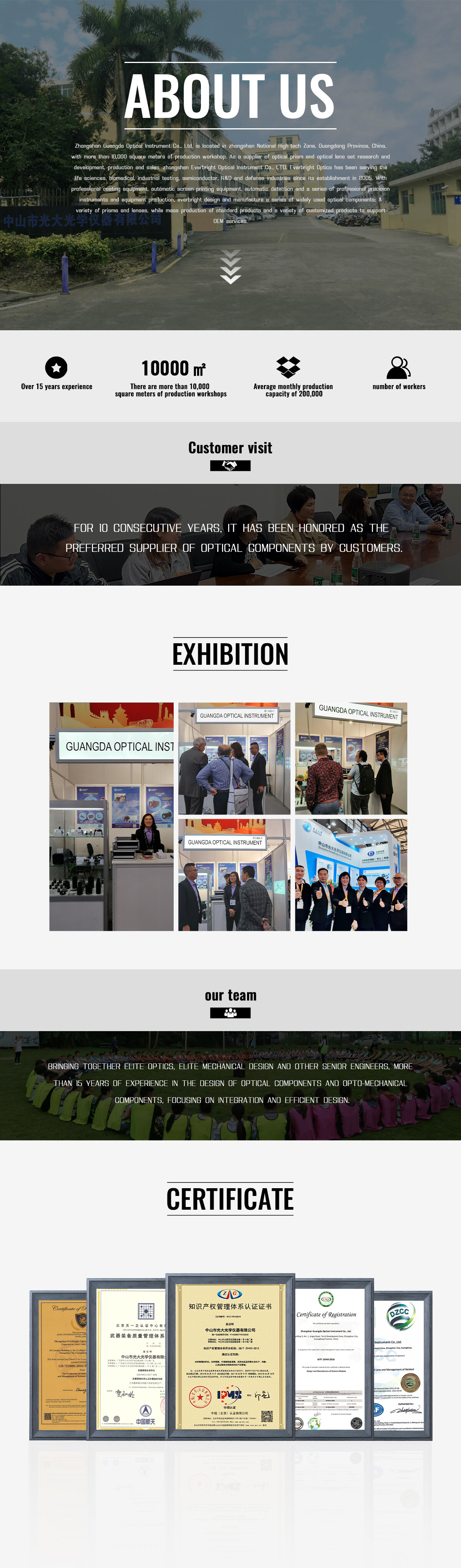

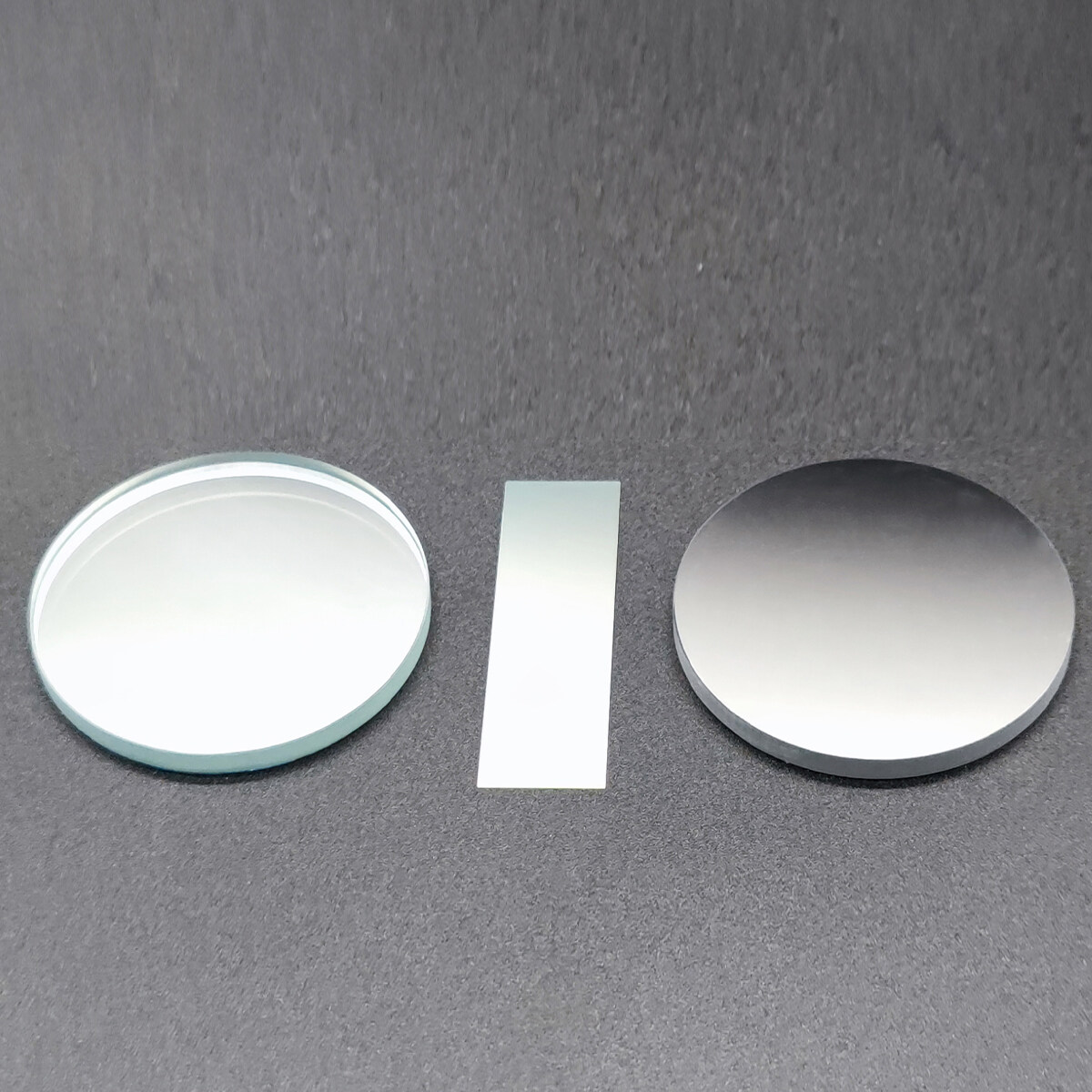

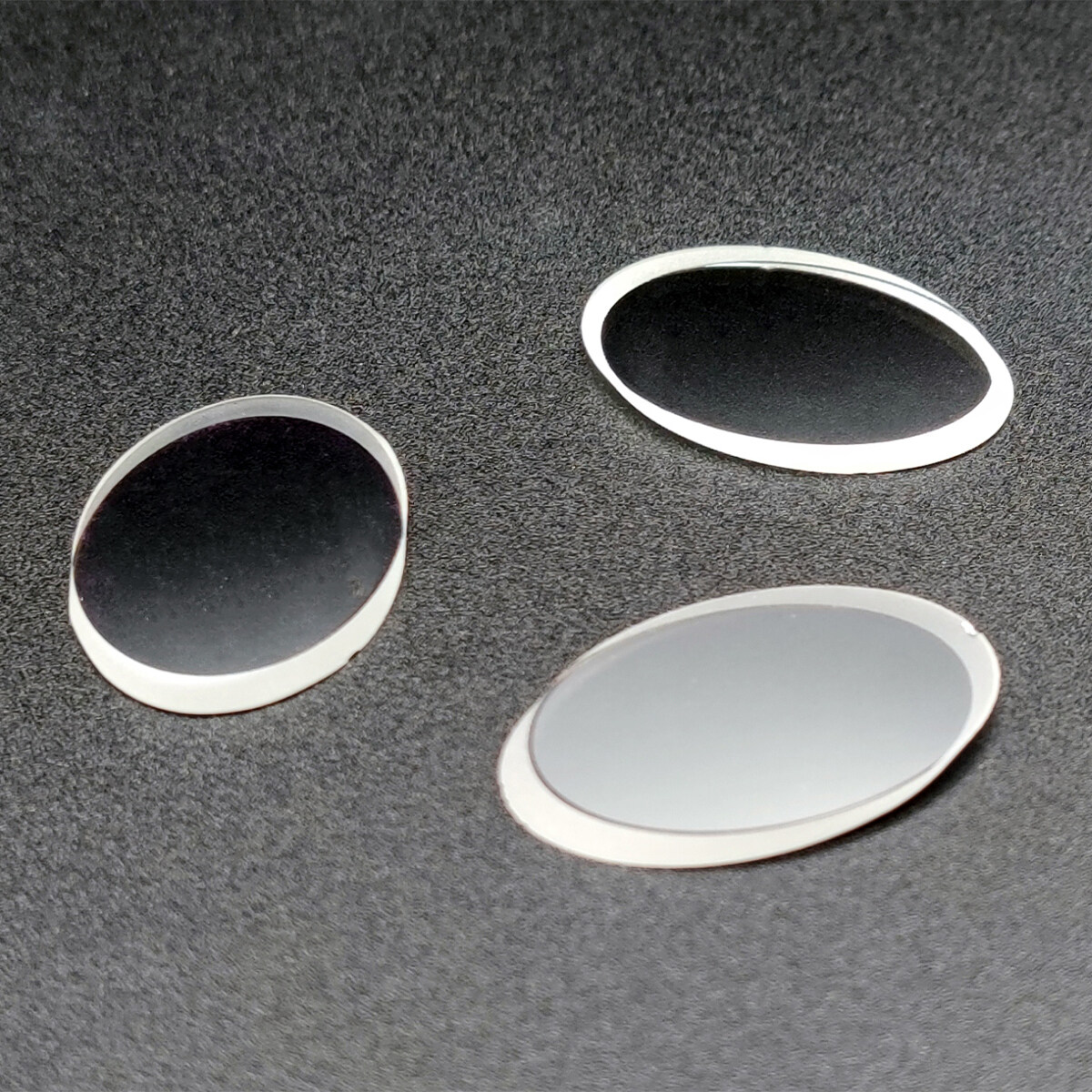

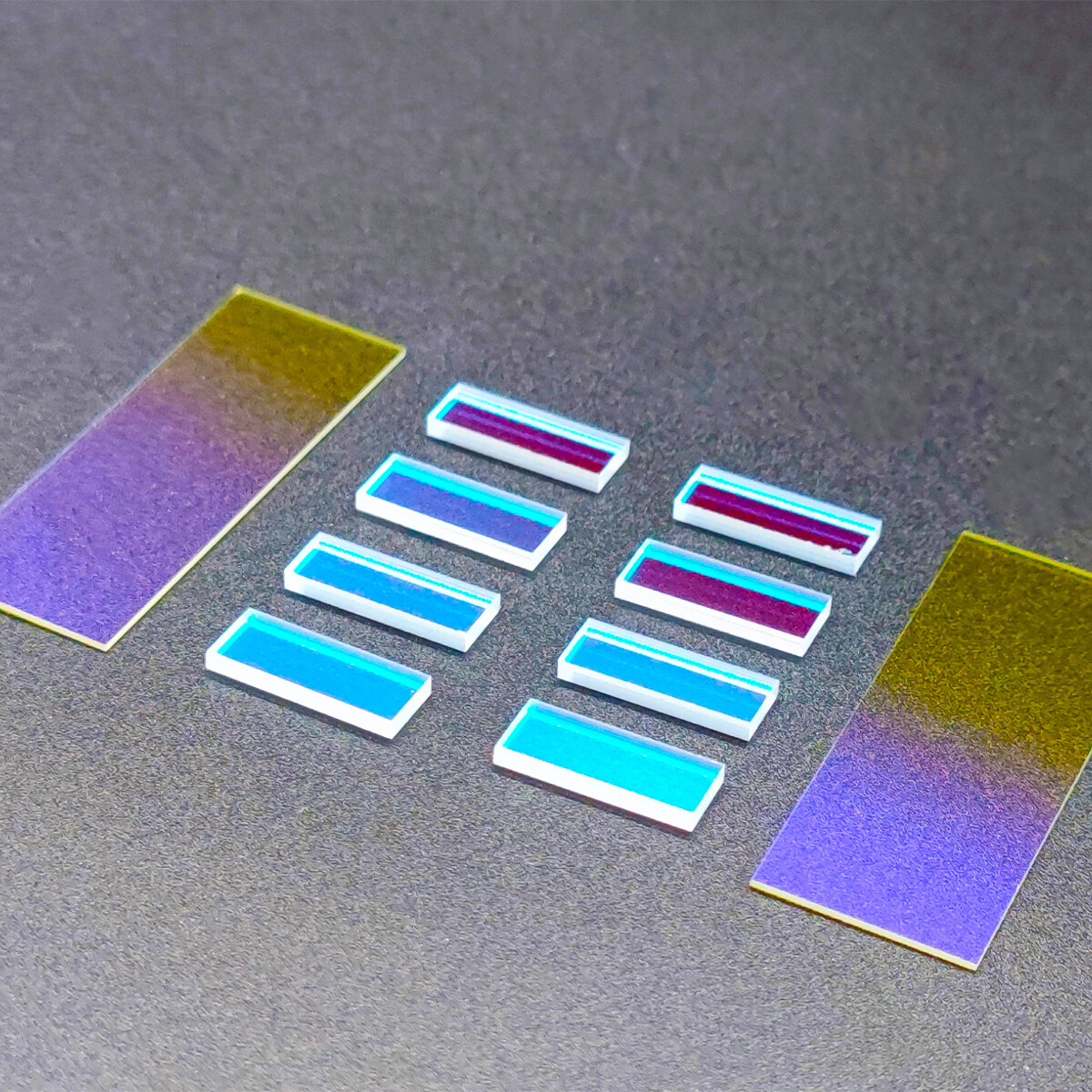

All Dielectric High Reflection Film

We are a reflective photoluminescent film manufacturer in China. The function of reflective film in floor heating is mainly to prevent heat loss from underground, to effectively improve the heat reflection and radiation ability, and ensure the constant indoor temperature.

Generally, metals have a large extinction coefficient. When the light beam is incident on the metal surface from the air, the amplitude of the light entering the metal decays rapidly, so that the light energy entering the metal decreases correspondingly, and the reflected light energy increases. The greater the extinction coefficient, the faster the attenuation of light amplitude, the less light energy entering the metal, and the higher the reflectivity. People always choose those metals with larger optical coefficients and more stable optical properties as metal film materials.

The thin metal materials commonly used in the ultraviolet region are aluminum, aluminum, and silver in the visible region, and gold, silver, and copper in the infrared region. In addition, chromium and platinum are often used as film materials for some special films. Because aluminum, silver, copper, and other materials are easy to oxidize in the air and reduce their performance, they must be protected by dielectric films. Commonly used protective film materials include silicon oxide, magnesium fluoride, silicon dioxide, aluminum oxide, etc.

1. What is a reflective film?

The advantages of the metal reflective film are simple preparation process and wide wavelength range; The disadvantage is that the light loss is large, and the reflectivity cannot be very high. To further improve the reflectivity of the metal reflective film, several layers of dielectric layers with a certain thickness can be plated on the outside of the film to form a metal-dielectric reflective film. It should be pointed out that the metal-dielectric film increases the reflectivity of a certain wavelength (or a certain wave region), but destroys the neutral reflection characteristics of the metal film.

All-dielectric reflection film is based on multi-beam interference. In contrast to the antireflective film, the reflectivity of the optical surface can be increased by plating a film with a refractive index higher than the base material on the optical surface. The simplest multilayer reflection is formed by alternating evaporation of two materials with high and low refractive indexes. The optical thickness of each layer is one-fourth of a certain wavelength. Under this condition, the reflected light vector on each interface participating in the superposition has the same vibration direction. The synthetic amplitude increases with the increase of the number of film layers.

2. Classification of reflective film

Reflective film is divided into dielectric high reflection film and metal high reflection film;

Among them, metal high reflection films are common

Reinforced aluminum: r>90%@400-700nm

Protective aluminum: r>87%@400-1200nm

UV protective aluminum: r>80%@250-700nm

Protective silver: r>95%@400-12000nm

Enhanced silver: r>98.5%@700-1100nm

Protective Gold: r>98%@2000-12000nm

3.Reflection film function

The function of reflective film in floor heating is mainly to prevent heat loss from underground, to effectively improve the heat reflection and radiation ability, and ensure the constant indoor temperature.

Reflective film is a kind of floor heating paving material, which is usually made of vacuum aluminized film and other materials, polyester film with color checkers, and glass fiber. The floor heating reflective film is made of soft aluminum foil with special treatment, heat-resistant PE adhesive, polyester film with color printing, and glass fiber. It has the characteristics of large output and low cost.

It is characterized by direct high-temperature extrusion and lamination, with firm adhesion and no delamination. The tensile strength of glass fiber densification increases and the hardness of foam board is enhanced. The surface is marked with size marks, which is easy to construct and fix the geothermal pipe.