Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

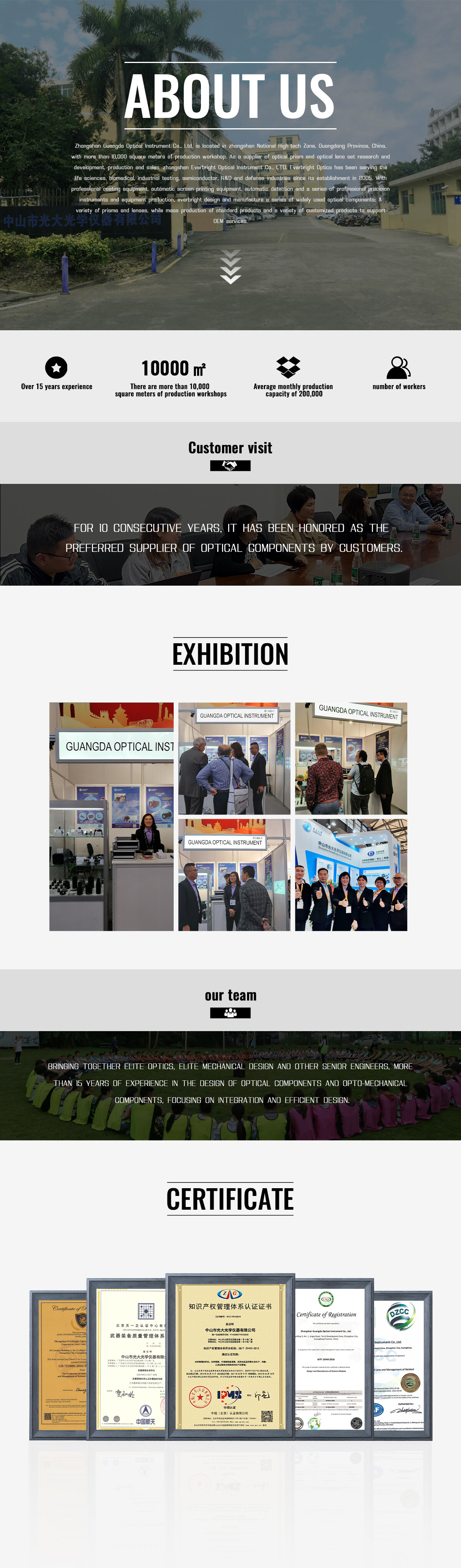

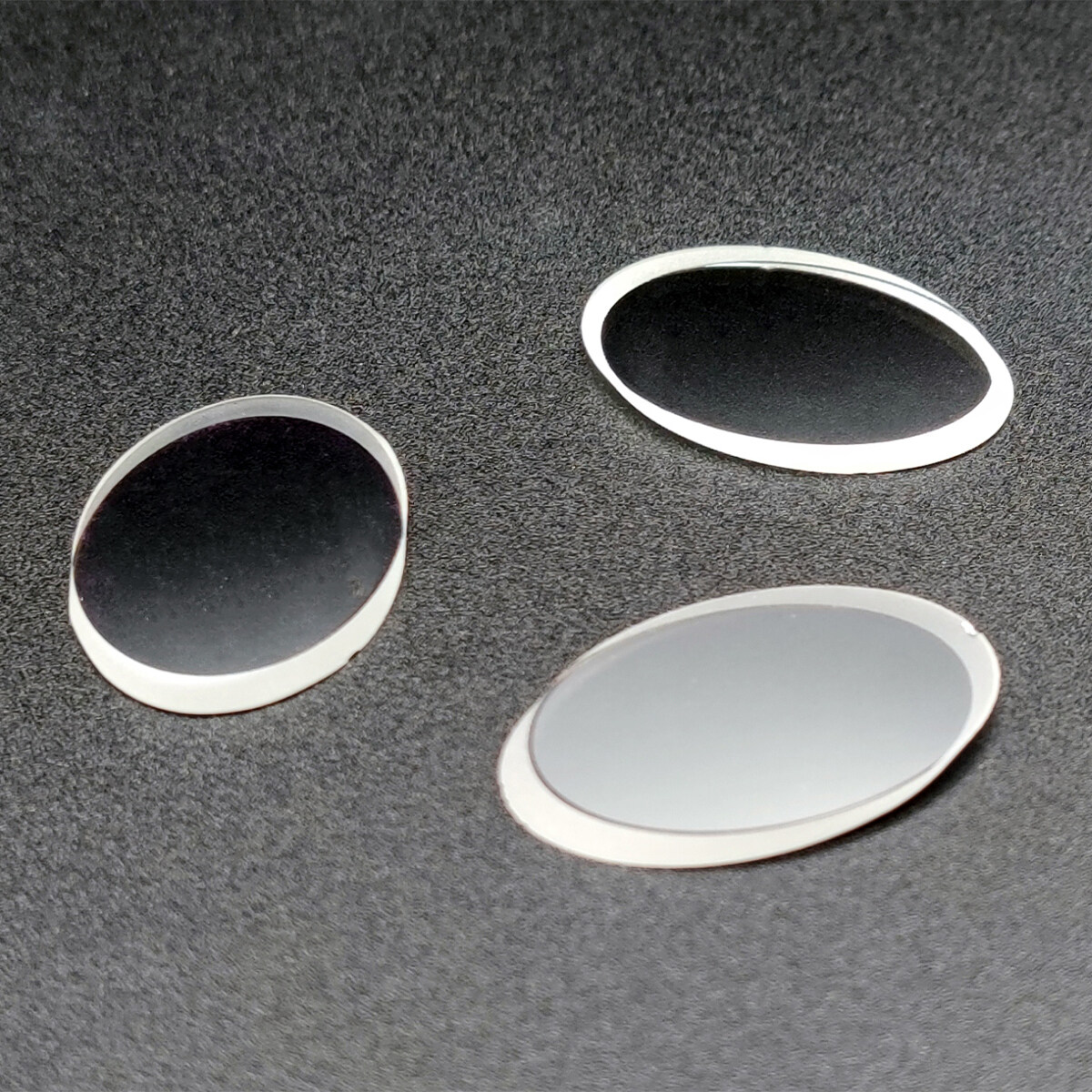

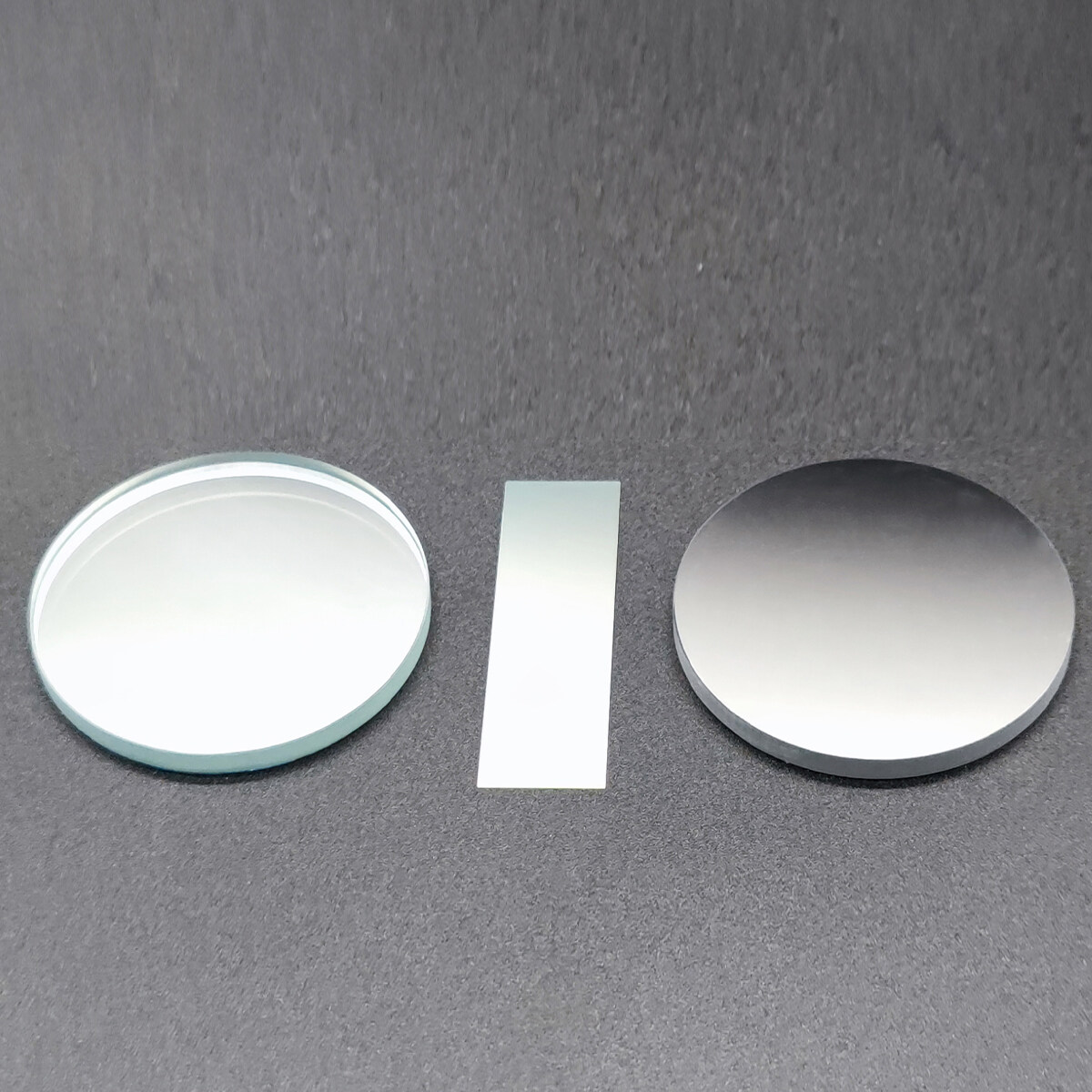

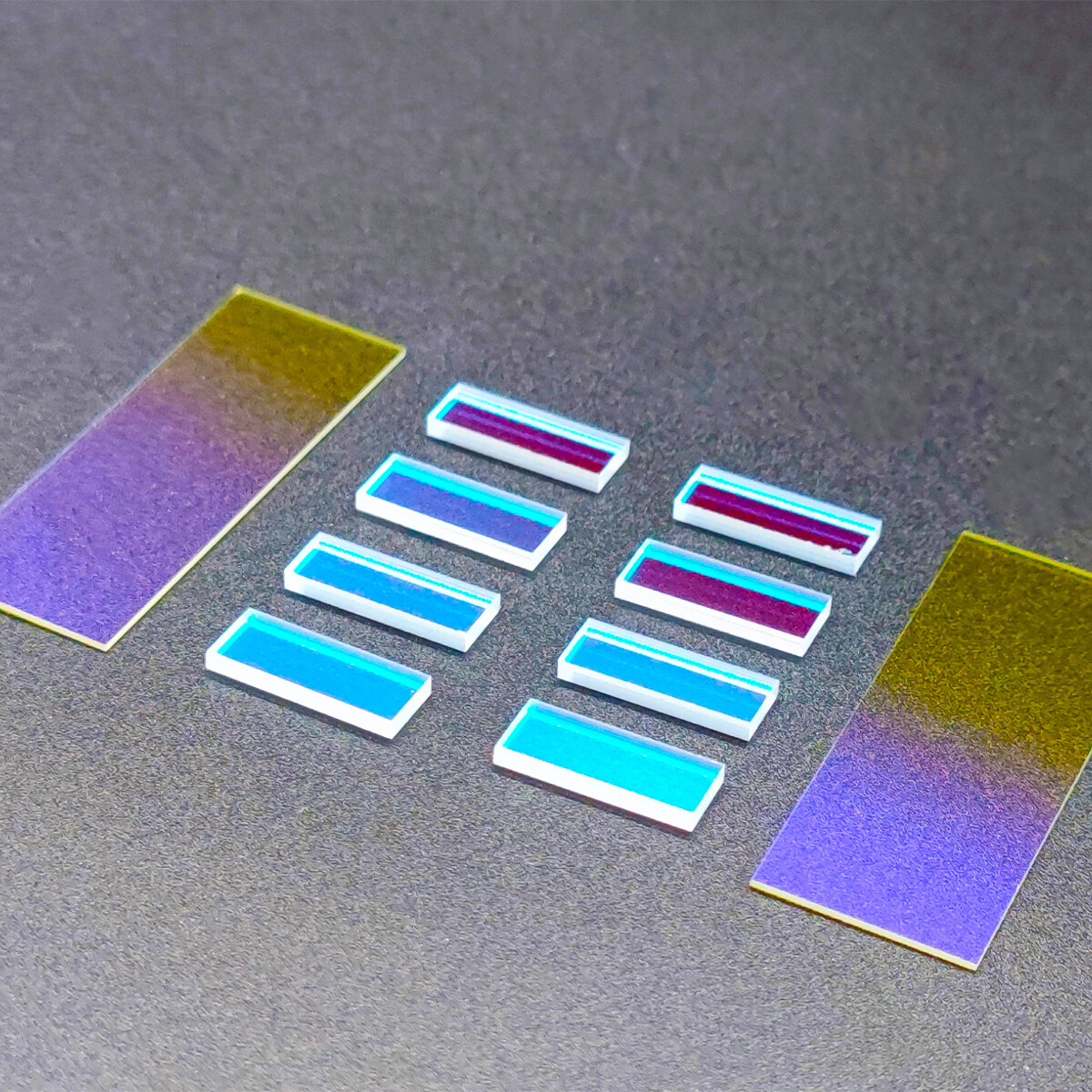

Laser Mirror

We are one of contemporary laser line mirror glass manufacturers in China.Our laser mirrors are designed for laser applications. Laser reflectors have compact surface quality, which can minimize scattering, and are suitable for beam steering applications.If you need this Laser Mirror,welcome to contact us..

Principle and application of laser mirror

The reflector is used as a tail mirror or turn-back mirror in the fiber laser system and a turning mirror in the external optical path system. Its substrate is usually molybdenum, fused quartz, oxygen-free copper, monocrystalline silicon, etc;

Oxygen-free copper materials are usually used in high-power laser systems because of their high thermal conductivity; Because monocrystalline silicon is cost-effective substrate material, the most commonly used substrate is "Silicon". Copper is usually used in high-power laser systems because of its high thermal conductivity. The wear-resistant surface of molybdenum is suitable for many specific physical environments, and molybdenum mirrors are generally not coated.

The optical applications of mirrors, high reflectors, and front surface reflectors are the same.

An optical element that reflects incident light by vacuum coating with a layer of metallic silver (or aluminum) film. The output power of the laser can be doubled by using a high reflectance mirror; And it is the reflection of the first reflecting surface. The reflected image is not distorted and has no ghosting. It is the reflection of the front surface. If an ordinary reflector is used as the second reflecting surface, it not only has low reflectivity, has no selectivity for wavelength, but also is easy to produce ghosting. Using the coated surface mirror, the image obtained is not only bright but also accurate without deviation, with clearer image quality and more realistic color. Front surface reflectors are widely used for optical high fidelity scanning reflection imaging.

The laser reflector is an important component in the laser fiber transmission system. In the CO2 laser optical path, the reflector can be used in two aspects. In the laser tube, the reflector can be used as a tail mirror, and the lens base has a certain curvature, which plays the role of oscillating the laser; In some laser designs, the laser reflector can change the light in the laser tube and reduce the length of the laser tube; Outside the laser tube, the reflector and the focusing lens cooperate to form a complete optical path, which makes the design of the laser machine more space-saving, reduces the laser loss as much as possible, and retains the laser working power to the greatest extent.

Generally, molybdenum and silicon are used as the substrates of the mirrors. Molybdenum mirrors can work in harsh environments, have a long service life, have high bearing power, have no coating on the surface, and are resistant to wiping. The disadvantage is low reflectivity. Silicon is the most commonly used substrate for coated mirrors, which has good optical and thermal properties.

Laser mirrors are designed for laser applications. Laser reflectors have compact surface quality, which can minimize scattering, and are suitable for beam steering applications. The dielectric film laser reflector optimized for the ordinary laser wavelength has higher reflectivity than the metal coating. The coating of laser spectral line mirror has a high damage threshold at its design wavelength, which helps to prevent laser damage and ensure long service life.